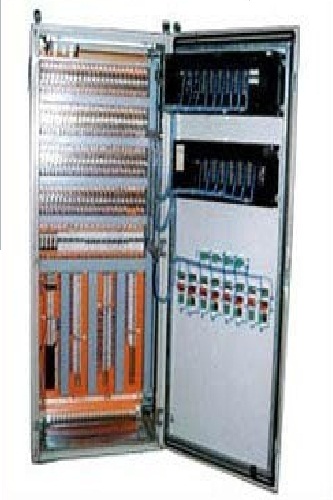

System & Marshalling Panel

Marshalling panel is placed between the DCS system panel and field instruments. Marshalling Panels provide cross wiring functionality between field instruments and the control system. By having this type of interface, input and output issues can be quickly identified and maintenance personnel can perform routine functions in the field without put at risk the heart of the control system. Marshalling is typically used in large DCS systems in refineries and chemical plants. Marshalling means grouping of I/Os. One of the interface function of the marshalling cabinet is the cross wiring function. Cross wiring is always necessary since the incoming field signal and the channel quantity of the I/O card is always different.

In marshalling panel grouping of I/Os like Analog Input, Analog Output, Digital Input, Digital Output and Pulse I/O are done. From marshalling panel the I/O signals are communicated to the system CPU/Controllers through Isolation/Signal conditioners.

VFD Panel

Variable Frequency Drive Panel is well recognized as VFD Control Panel; which is developed to organize or manage the speed of electric motor and feed pump. VFD Panel generally use in pumping, drilling and large industrial machine uses. The VFD panels are broadly used in CTL Lines, rolling Mills, cable industry, tube mills, paper mills and extruder plants. We offer an extensive range of VFD Control Panels that is a speed drive that provides a means of driving and adjusting the operating speed of a mechanical load. We offer the VFD Control Panel in variable frequency drive. Fully equipped with all the necessary switch gears, this range of VFD Control Panels finds its wide applications in diverse applications. We also customize our VFD Control Panels as per the demand of the clients.

PCC Panel

Power Control Centre measured to be the base of an electrical organism in any industry. Hence it shall present users long term dependability, protection, low maintenance & testing time. Power Control Centre (PCC) is used for distribution and control of different power source used in industry. Usually Power Control Centers is set up near power source hence fault level is high. It is planned to suit fault level of 50KA or 65 KA for 1 sec. Power Control Centers are intended to suit the fault level as well as temperature rise to 40°c above ambient. These are accessible in a wide range (from 630A to 6300 A) to match every user’s requirement. Main LT Panel, PCC With single, multiple incomer, bus couplers with proper interlocking Required protection, fault indications, interlocking is provided. Various designs are offered in PCC like top, Middle, Bottom Horizontal bus chamber, panel with aluminum/copper bus bars, top/bottom/front/rear cable termination, combinations of APFC Part with PCC.

APFC panel

APFC Panel is completely mechanical in function and can realize preferred power factor under variable load conditions. We offering the installation and examine solutions for any types of APFC Panels and Controllers. In now days the majority of the commercial and Industrial setting up large electrical loads; which are harshly inductive in nature for example large machines, motors, drivers, air conditioners etc, it fallout in a severely lagging power aspect. This means loss & expenditure of energy and heavy consequence by electrical boards. In case of permanent loads this can be taken care by physical switching of capacitors yet in case of quickly unstable & scattered loads it turns into tricky to continue a high power factor by physically switching on or off the capacitors in quantity to difference of load within an installation. This disadvantage is defeat by using an APFC panel (Automatic Power Factor Correction Panel) which not only keep high power factor but also reduces the need for regular manual intervention.

Automatic Mains Failure Panel

The Logic of AMF Panel is when Main Power Cut off then DG Set on By AMF panel and Power change Over Main supply To DG Supply .In AMF panel there are electronic Relay Is use for Sensing Power. The Power and Control Instrument are using In Panel Are ACB OR MCCB, contactor, AMF Relay, Battery and Battery charger, Multifunction meter and other. AMF Panel is also Have Protection of DG SET Like H Water cooling Temperature High, DG Set Overload, phase Loss or phase Unbalance. AMF panel design of Capacity up to 550 KVA AMF Panel Also Have Auto and Manual Mode System.

PDB Panel

Power Distribution Panel are using in applications like power-distribution, control, ground-fault protection and monitoring. Apart from this, Power Distribution Panel also serves as alarm panel for freeze protection, broad temperature-maintenance and heat-tracing applications. These Power Distribution Panels are integrated with ground-fault circuit breakers in an enclosure having assembled circuit-breaker panel board with or without alarms contacts. Furthermore, equipped with the group control package, Power Distribution Panels have the capability of automating operation in conjunction with an ambient-sensing thermostat, individual electronic or duty cycle controller.

PLC Control Panel

A programmable logic controller, PLC, or programmable controller is a digital computer used for automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many machines, in many industries. Ease in modification of logic, reduced size, means of remote communications and advances in the technology have made PLC Automation Control Panels an edge over conventional relay based systems. Control Systems Engineers has provided PLC based Panels from PLC of Honeywell, GE Fanuc. From small I/O application to the complex I/O systems are provided by the Control Systems Engineers. Control Systems Engineers have developed communication software's for remote communication of the PLC Panels in various different protocols. With PLC based Panels HMI/MMI are provided to provide the operator various messages and controls of the process plants touch screen MMI are provided.

Relay Logic Panel

The relay panel is an electrical unit used for hardwired signals with digital inputs and outputs that interfaces between the control equipment and circuit breakers. A control & relay panel is designed to provide to control the associated line or transformer through outdoor switchgear at various zonal substations. The control & Relay panels are complete in themselves with all main and auxiliary relays, annunciation relay, fuses, links, switches, wiring, labels, terminal blocks, earthen terminals, base frame, foundation bolts, illumination, cable glands etc. These panels are used for the control & monitoring of electrical equipment’s such as transformers, generators and circuit breakers. Indoor Control panel for outdoor VCB etc. These control & Relays panels are available in various combinations as single circuit or multi-circuit depending upon the customer requirements.